Water supply is one of the first areas to inspect on a poultry farm when operations are not performing properly. Knowing how to estimate the amount of water needed by your birds and how to test systems for adequate water flow is essential.

Every poultry house must have a sufficient water supply to meet the peak flow demands for birds, evaporative pads, and other needs. The water demand in gallons per minute (GPM) required by a modern broiler house depends on several factors:

- Number of birds placed in the house

- Total tunnel air capacity in cubic feet per minute (cfm) installed in the house

- Other water demands on the house (e.g., wash-down faucet)

Following are two simplified examples of how GPM is estimated:

Example 1

- 40′ × 500′ broiler house with 20,000 birds, 250,000 cfm of fan power, and wash-down faucet

- 2 GPM for birds + 10 GPM for pads + 3 GPM for wash down = 15 GPM total per house

Example 2

- 66′ × 600′ broiler house with 40,000 birds, 450,000 cfm of fan power, and wash-down faucet

- 4 GPM for birds + 18 GPM for pads + 3 GPM for wash down = 25 GPM total per house

Estimating Water for Birds

Figure 1. This demonstration device is used to train producers to estimate bird water demands, test water supply capacity, and troubleshoot water supply restrictions.

There are two ways to estimate bird water consumption:

Method 1

1. Take the total 24-hour metered reading from the water meter or meters.

Example: 2,400 gallons per day (gpd) in a 24-hour period

2. Determine how many hours the lights were off and birds were resting and not drinking.

Example: 4 hours of dark = 20 hours of lights on

2,400 gpd / 20 hours = 120 average gallons per hour (gph) lights on

120 gph / 60 minutes = 2 GPM (average estimated water flow when lights on and birds drinking)

Method 2

A good starting point for estimating large bird water use is 0.1 GPM (0.08 GPM for smaller birds) of water flow for every 1,000 birds. (See Poultry Housing Tips, Broiler Farm Water Usage and Pipe Sizing Rules of Thumb, University of Georgia Extension publication.)

Example: 20,000 birds housed

20,000 / 1,000 × 0.1 GPM (20 × 0.1 GPM) = 2 GPM needed for birds

The estimated 2 GPM is the average flow rate for a day at market age. This amount will not be adequate, however, during peak consumption periods. If the supply provides 2 GPM but the birds need 3 GPM of flow when the lights come on in the early morning and daybreak stimulates activity, performance could be negatively affected.

The recommendation is to supply about 1.5 to 2 times the average water flow to the drinker system to cover peak periods (e.g., 2 GPM × 2 = 4 GPM of estimated continuous flow to the drinkers at all times). Maintaining this goal of 4 GPM of water flow should manage the peak demands for the birds with some room for error.

Simple Water Flow Test Procedure

Figure 2. A water flow bucket test revealed the existing dirty filter (left) produced only 1.7 GPM. After a new filter (right) was installed, the test measured over 13 GPM. Dirty filters can be very restrictive to water flow if allowed to go unchecked.

Sometimes poultry houses are managed well but still do not perform and compete as they should. If this situation sounds familiar, it is time to perform a water flow test in those houses.

Step 1. Gather a 5-gallon bucket, a 3/4-inch minimum jumper hose, and a timer to perform the flow test (figure 2). If you have not done this before, it might be helpful to read “NPTC Tools of the Trade: Measuring Water Flow Rate” (Extension publication ANR-2827).

Step 2. Run the water in all houses. It is best and easiest to conduct this test when the farm is already under full water demand with large birds, full tunnel, and maximum pad operation (e.g., a 95-degree F day with 50 percent relative humidity and 55-day-old birds, or whatever the final days of market age growth would be).

Step 3. Evaluate each house on the farm while the rest of the farm is under maximum demand. Compare the flow rates to those estimated in the previous examples. This is usually done using a 3/4-inch minimum ball valve directly from the water panel, after the filter, regulator, and meter if possible. If there is only a water hose faucet, the test will be helpful but will restrict the water flow during the test. To determine if you have restrictive faucets, refer to “Do Your Valves and Hose Bibs Restrict Water Capacity? (Extension publication ANR-2721).

The supply will be adequate if the house passes the test with 6 GPM through a restrictive faucet. If the estimate is 2 GPM and you only get 2 GPM, change the filters upstream if possible and plan an inspection after the flock is sold.

If the house water flow is less than needed during the test, a serious inspection of each component upstream should be prioritized. Installation of PVC unions on both sides of any component during this process is recommended. Unions allow you to routinely check regulators, medicators, and filters for signs of corrosion or debris restrictions. Plumbing work is not recommended while the flock is in-house unless it is absolutely required.

Estimating Water for the Pads

Six-inch evaporative cooling pads can consume significant water on a hot, dry day. For much of the broiler belt, we can assume these systems will consume about 4 GPM for every 100,000 cfm of fan power on a house. Plumbing systems are typically designed to supply 5 GPM of water flow for every 100,000 cfm of tunnel fan power to manage peak demands. As peak demand estimates, the example at the beginning used 10 GPM for a 40-foot house and 18 GPM for a 66-foot-wide house.

The same testing procedures can be conducted at each water supply point in each cooling system. It is essential to supply the designed water capacity to each cooling system unit so that water flow is not taken from the birds during peak cooling demand periods.

If a house fails the test at the pads but passes the test in the control room, you may have a restriction somewhere between the control room and the evaporative system water supply point. If the house fails the test in the control room, more focus should be on the supply system to the house or farm.

More information on estimating evaporative cooling water system demands can be found in these resources:

- Evaporative Cooling Pad System Water Usage (Volume 29 Number 1, University of Georgia)

- “How Much Water Does Your Evaporative Cooling System Need?” (Mississippi State Extension publication P3329)

Putting It All Together

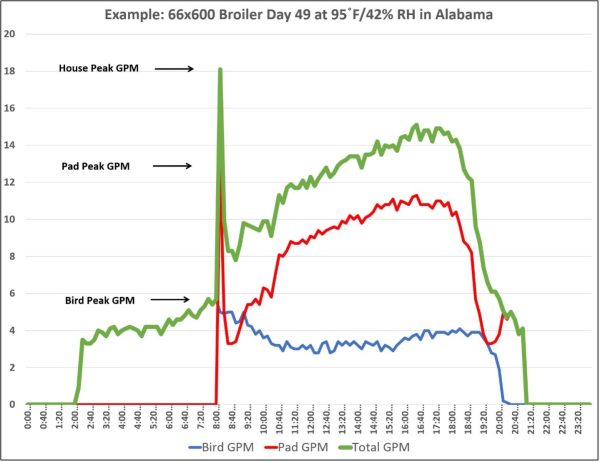

Figure 3. Example water GPM for birds, pads, and total flow

Figure 3 illustrates the water flow (GPM) of a 66′ × 600′ broiler house containing 44,000 birds on a hot day. Lights come on at 2:00 a.m. and birds begin to drink. Peak water meter flow occurs at 8:00 a.m. Applying the general rule of 0.1 GPM for every 1,000 birds, the estimated peak for birds is 4.4 GPM; however, 5.7 GPM is reached in this case.

The birds reach the estimated 4.4 GPM threshold at 6:00 a.m., and the bird flow rate remains above this until 9:20 a.m. That means the bird rate exceeds the estimated average rate for 3 hours. If this house can provide only the estimated 4.4 GPM or less, the flock will not get adequate supply during this period and for the duration of the grow out.

Notice that the pads in this example reach 13.1 GPM on this day at 8:10 a.m., bringing the maximum measured house total to 18.1 GPM. This house consumes 4,076 gallons of water for the birds and 6,352 for the evaporative pads for a total of 10,428 gallons in one day. What’s more, this is not the hottest or driest day of the year, and the flock is not maximum age or size.

Summary

Producer loss of income can be significant if major water supply restrictions exist on a farm. Losses can be an estimated 3 percent reduction in livability and 0.5-pound reduction in average sale weight. That would be a loss of $3,603.60 ($900.90/house) on four 40′ × 500′ houses and $7,207.20 ($1,801.80/house) on four 66′ × 600′ houses.

A few hours of troubleshooting to identify the source of the problem and investment in new plumbing parts to correct the problem can result in a rapid payback. If you are uncomfortable doing plumbing repair or maintenance, consider contacting a local plumber for professional help.

Estimating water demand needs for a single house is based on many factors, such as the number, type, and size of birds housed, total tunnel exhaust fan air capacity, evaporative cooling system size and media type, geographic location, feed formulation, drinker type and management, and producer management differences. The information presented here is for estimation and troubleshooting purposes only. For more information, visit poultryhouse.com.

Jess Campbell, Assistant Extension Professor, Jeremiah Davis, Associate Professor and Director, Kelly Griggs, Research Engineer II, Carson Edge, Research Engineer, and Cody Smith, Research Engineer, all with the National Poultry Technology Center, Auburn University

New August 2022, Poultry Farm Water Supply Troubleshooting, ANR-2911